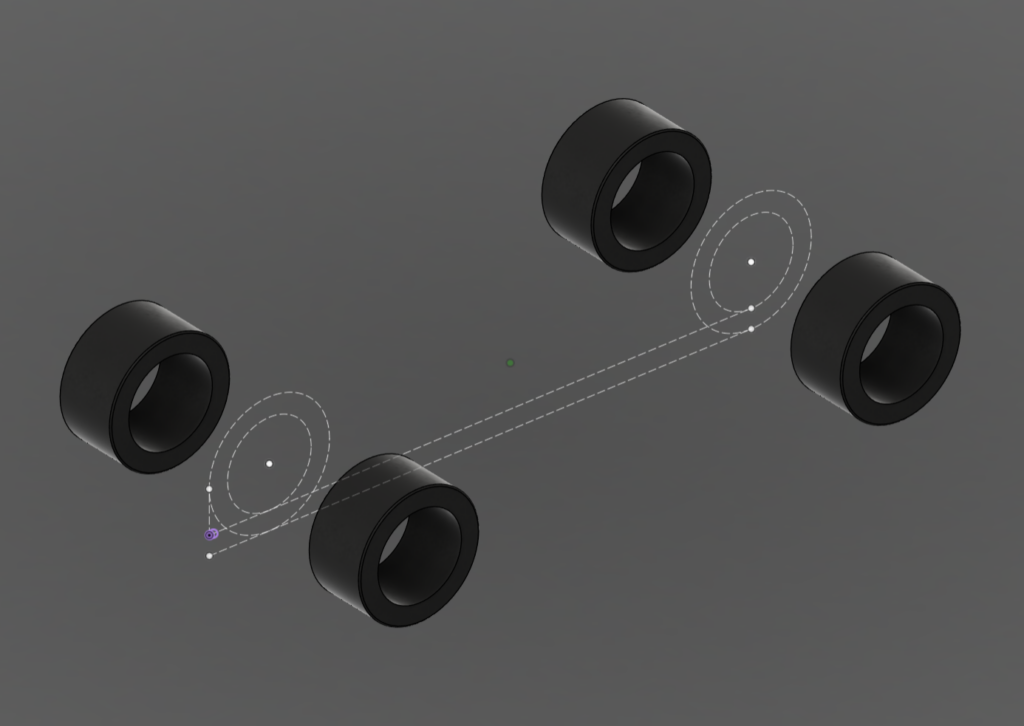

The front and rear differentials will be mounted to the chassis like a 2020 Ford F150, not through the oil sump like a Nissan GTR or AWD BMW.

The front and rear differentials don’t need to be from the same vehicle, but they do need to have matching final drives.

Ideally the differentials would be readily available at an affordable price, and have a wide range of final drive ring gear options so i can fine tune the gearing mph/rpm of the shift points. Also, they should either be strong enough from the factory to support the power goal, or have enough aftermarket support to allow for them to be built up to support the power goal.

I am considering 3 options

- Ford 8.8″ IFS & IRS Diffs

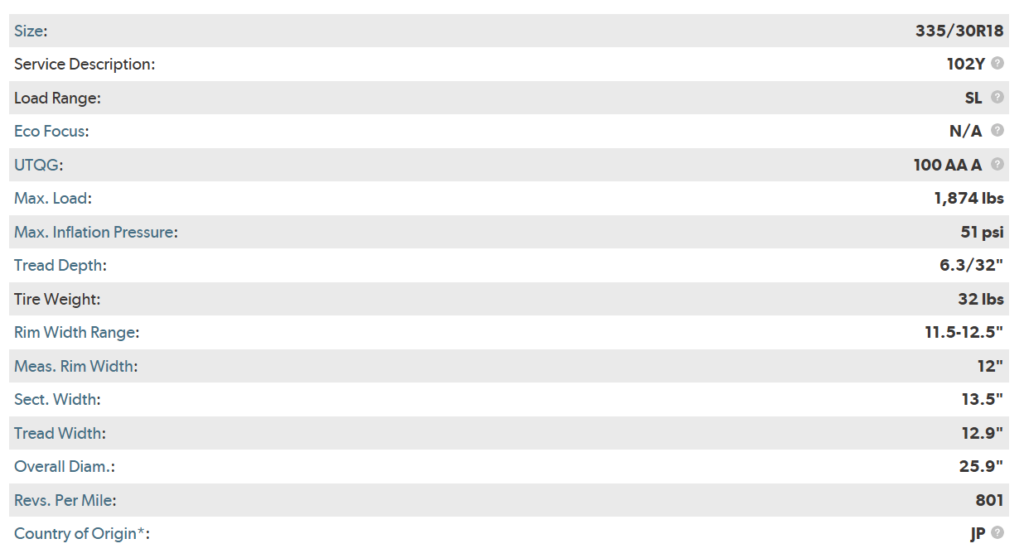

The 2020 Ford F150 came with an affordable 8.8″ aluminum housing chassis mounted independent front differential that comes with a housing that has a built in intermediate shaft housing so that both front axles can be equal length and has lots of ring gear options for different final drives. It lives relatively well in 1000whp twin turbo Coyote v8 F150 4WD drag racing applications. The 2010 Ford Explorer came with an affordable 8.8″ aluminum housing independent rear differential with lots of ring gear options for different final drives. It is a very popular rear end upgrade for many vehicles. The downside here is that the 8.8″ front diff is physically very large to fit in front of the engine. Since it has a built in intermediate shaft, and ideally the front axles would be the same length, I would want to use it with an engine that is narrow enough to allow for the front diff to be centered (left to right) in the frame without hitting the engine. Final drive ratios of 3.09, 3.15, 3.27, 3.31, 3.55, 3.73, 4.10, and 4.56 are available.

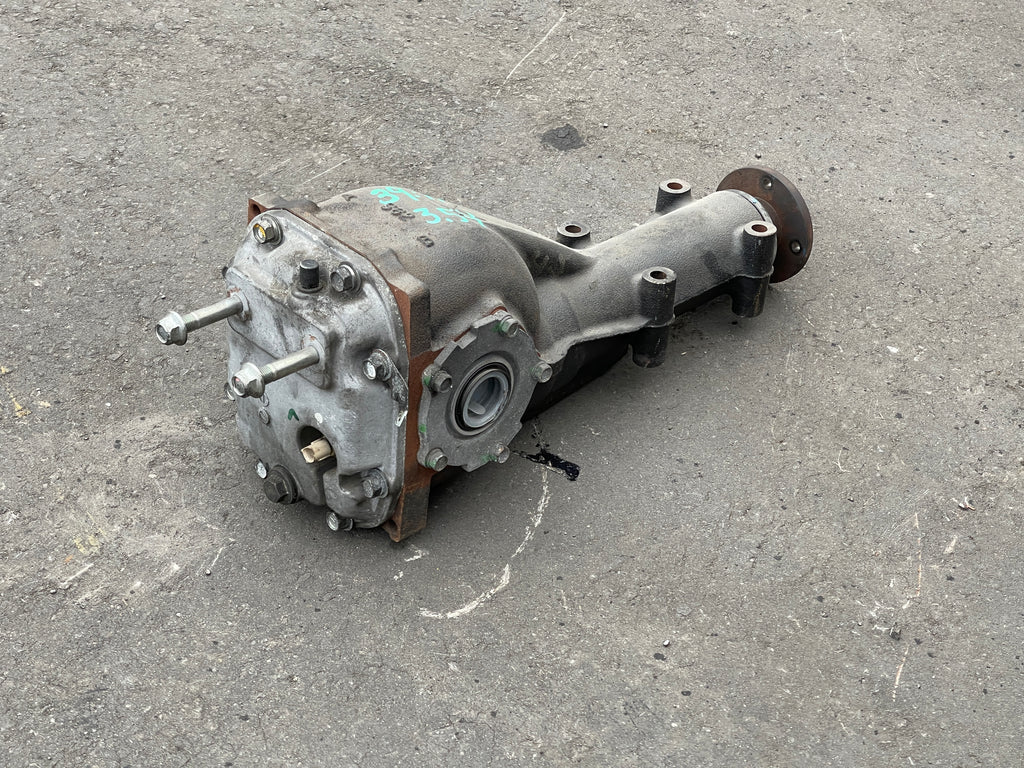

- Two Subaru Rear Diffs (one turned around and flipped upside down in front)

Subaru makes a strong but compact R180 rear differential, and an even smaller R160 rear differential with matching ring gear ratios and both came as LSD’s from the factory. The smaller R160 rear differential could be turned around and flipped upside down to be used as a front differential. These diffs are readily available, strong, compact, and reasonably affordable. But the front one will require an intermediate shaft and carrier to be fabricated so that the front axles can be the same length. Final drive ratios of 3.54, 3.90, and 4.44 are available.

- Nissan GTR Front and Rear Diffs

The Nissan GT-R front diff is designed to mount to the oil pan and the engine sits on top of the axle line. But a bracket could be fabricated to chassis mount it in front of the engine. These diffs are strong and small, but they are expensive and less readily available. The R32 differentials have a final drive of 4.11 and the R35 final drive is 3.70

some considerations:

The Toyota 2JZ engine has the turbos on the right side of the car. The turbos are one of the heavier components in the car that can be strategically placed for center of gravity optimization. Ideally they would be mounted as low and centered as possibly without negatively impacting their ability to gravity drain oil into the sump. Then there must be room for the down pipes and exhaust to come out of the turbos and down the tunnel to the back of the car. And in addition to all of that, there is also an engine mount in that same area. This would make a right side driveshaft configuration (like the Nissan gtr) more difficult to package. The turbos would have to be top mounted with the driveshaft running under them and the exhaust would have to pass around the front driveshaft somehow.